90 years of strength and innovation

In a world where companies frequently change owners or disappear in the face of competition, it’s rare to find a business that has remained in the same family for 90 years. EWES, Sweden’s oldest privately owned spring manufacturer, has evolved over generations – from a small workshop in southern Sweden into a global player in technical springs 💙

Milestones – EWES

From furniture and toys to high-tech springs

The story of EWES begins in 1935 in Bredaryd, southern Sweden. Einar and his wife Irma Svensson opened a small metal workshop where they produced seat springs and wire components for the local furniture and toy industries. During the war years, the business became a side income, but the couple held on to their vision and saw a greater potential. After World War II, as the world began to recover, EWES gained momentum. The company shifted focus and began manufacturing technical springs for industrial use – a decision that would shape its future.

EWES’ first factory was modestly housed in an outbuilding on the family’s property – a humble start for what would become a leading spring manufacturer.

Two generations of the Svensson family: son Kjell in the center, flanked by his father Einar and mother Irma.

Germany – a natural home market

Germany quickly became a key market for EWES, particularly in the quest for advanced machinery. As early as 1949, Einar travelled to Hannover for his first – but far from last – trade fair visit. It was the first industrial fair after the war, and his previous correspondence course in German proved very useful.

Ahead of the trip, he had obtained brochures and requested technical documentation directly from Germany. At the fair, his choice was confirmed, and he placed an order for EWES’ first fully automated spring coiling machine – from the company Karl Hack. With it, the company could, for the first time, manufacture springs without relying on manual labour or lathes.

Despite obstacles such as complicated export permits and material shortages – which meant the machine wasn’t delivered until 1952 (!) – this marked a decisive step in EWES’ international expansion. A fun fact: the machine still exists in the company’s possession, now restored as a showpiece. In its heyday, local villagers would gather at the factory and spend hours simply marvelling at the brilliance of German engineering.

From Spring Calculations to Global Breakthrough: The Xerox Story

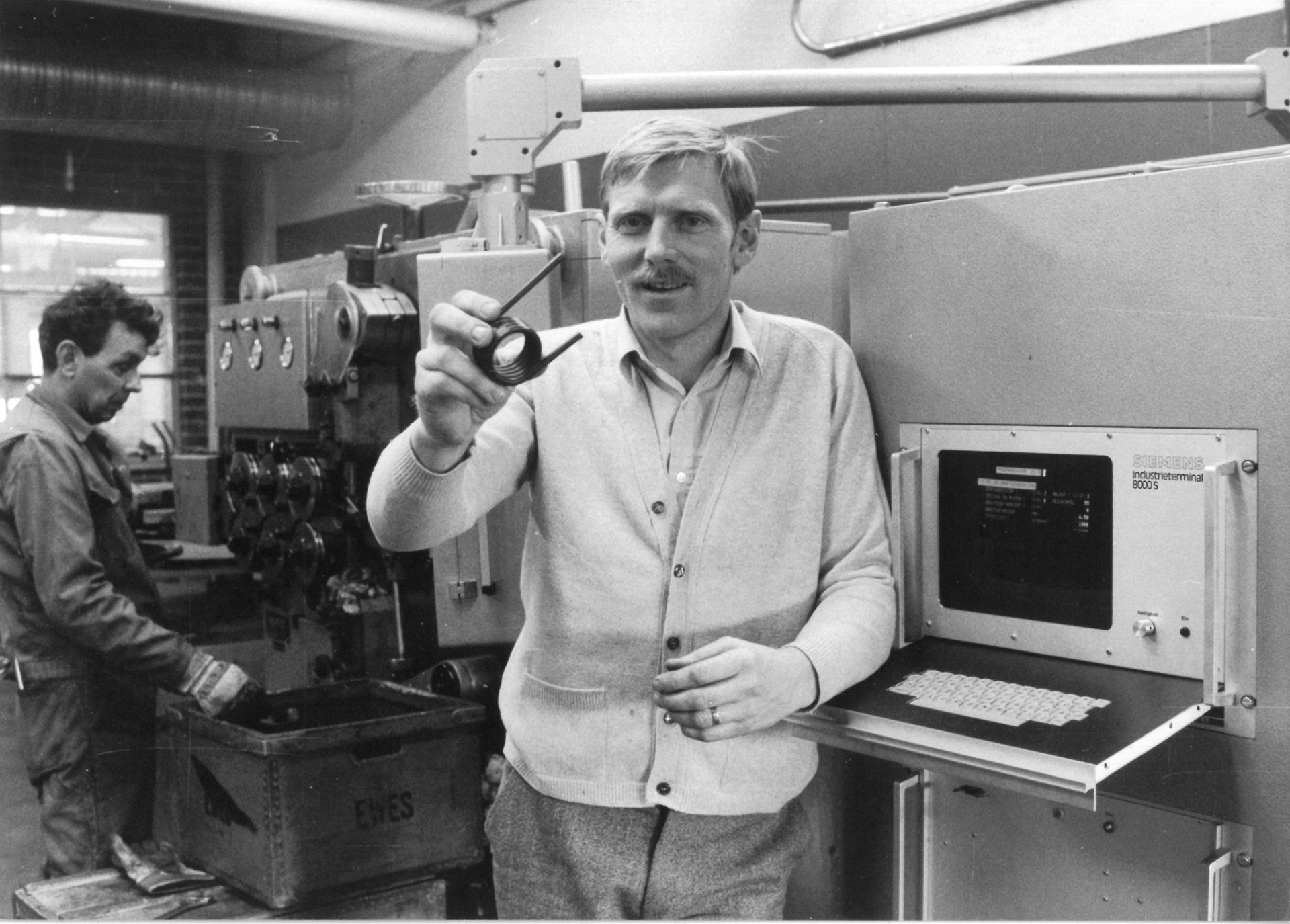

In the 1980s, EWES took a bold leap into the future by becoming the first company in the world to use a computer – programmed in Basic – to calculate spring dimensions with high precision. Previously, the industry had relied on slide rules, nomograms, and tables – methods with large tolerances and a lot of guesswork. The new technology brought precision to measurements and forces. It marked a decisive step forward: for the first time, the gap between design specifications and actual production could be bridged.

The brothers Kjell and Klas Svensson traveled the world to demonstrate what the technology could achieve – for both customers and suppliers. One of their stops was Rank Xerox, which was struggling with a new copier model where the paper wasn’t feeding properly from the tray. EWES analyzed the spring design using their computer and quickly identified the problem. The existing spring had been selected from a standard catalog and wasn’t custom-designed for Xerox – leading to deviations in both force and dimensions. With EWES’ precise calculations, the issue was quickly and effectively resolved.

With a pocket computer programmed in Basic, EWES revolutionized spring manufacturing—bringing accurate dimensions to the industry for the first time.

Klas Svensson, brother of Kjell and part of the second generation in the family business, played a key role in the collaboration with Xerox and the spring factory in Canada. He passed away in 1994, but his contributions live on.

Canada’s largest spring factory – brought to life by the Svensson brothers

Xerox are pleased with EWES’ work and eager to take the partnership further. The next step is to establish a local operation in Canada – offering benefits such as duty-free trade, smoother logistics, and a favorable exchange rate. The Svensson brothers partnered with two Canadians who spun piano wire springs by day and manufactured mechanical springs by night. Together, they built a spring business that grew rapidly. In addition to Xerox, Chevrolet also became a major customer, and during the 1990s, the factory became the largest spring producer in Canada.

But in 1994, the family suffered a major loss. Klas passed away from cancer, leaving Kjell as the sole leader. He then made the decision to sell the Canadian operation and focus fully on growing the family business back in Sweden – together with his remaining siblings.

Tradition, innovation, and a future-focused vision

Today, under the leadership of the third generation – Anton Svensson and his cousin Anders Cederquist – EWES continues its legacy of innovation. Over the decades, the company has evolved alongside its customers, adapting to both technological shifts and new industrial needs. What began as a small workshop in southern Sweden is now a modern manufacturer of technical springs with a clear vision for the future.

Cousins from the third generation are leading EWES into the future. R&D Manager Anders Cederquist (left) and CEO Anton Svensson (right) are building on the family legacy.

EWES in Sweden – more than 8,000 square meters of innovation with the goal of having the most advanced machinery in Europe. Global presence through subsidiaries in Serbia, Bosnia, and China.

Global Presence and a commitment to sustainability

To better serve customers in various markets, EWES has established subsidiaries in China, Hong Kong, Bosnia, and Serbia. The company believes in the value of a sustainable local presence and has therefore started production near its customers. This strategy ensures that products and services are available where they’re most needed – while still maintaining a global reach.

A particularly important part of EWES’ exports includes environmental products – such as mast electrodes and emission electrodes used in electrostatic precipitators that capture particles from flue gases. This technology is common in heating plants, the steel industry, and other process industries worldwide, where it helps reduce emissions, including those from coal combustion. The products are made in Sweden but shipped globally – from China to the Americas. EWES’ environmental line is a clear example of how innovation and sustainability can go hand in hand.